Jungheinrich is building a new logistics centre for WEGMANN automotive in Veitshöchheim, Lower Franconia. This major project at the company’s headquarters is scheduled to be completed by the end of 2021. WEGMANN automotive is the global market leader for balance weights and battery bushings for automotive production. The company is the exclusive supplier to Formula 1 and supplies all notable automotive manufacturers as well as leading retail organisations.

The new logistics centre at WEGMANN automotive’s headquarters near Würzburg has been designed to utilise automated warehouse systems to increase handling performance through fast access times. Error rates will remain low while the use of space will be maximized. Jungheinrich will supply the company with a comprehensive solution from a single source. This includes everything from the detailed planning of processes in both the new and the existing buildings to the supply of modern technology. The heart of the project is a high-bay warehouse featuring automated pallet conveyor technology. Stacker cranes from Jungheinrich subsidiary MIAS allow for automated storage inclusive of control units and visualisation.

Automated guided vehicles from Jungheinrich will keep material flowing through the logistics centre. Three-phase AC technology enables long deployment times. The automated guided vehicles are navigated by laser technology which is connected to reflectors along the warehouse aisles. The AGVs receive all information via the Jungheinrich Logistics Interface. This interface connects Jungheinrich’s trucks directly with WEGMANN automotive’s SAP EWM system.

The new automation solution also includes lift racks that provide optimal utilisation of space. To make small parts picking effective, the lift racks and trays are directly connected to the customer’s SAP EWM system through Jungheinrich’s logistics interface. This ensures optimum process transparency.

Following completion, WEGMANN automotive’s new logistics centre will process internal and external incoming goods, storage, order picking and shipping at the most advanced level. The scope of supply includes a Jungheinrich service and maintenance package and original replacement parts for all equipment.

Follow us

Aboneaza-te la newsleter

International

WEGMANN automotive RELIES ON AUTOMATION FROM JUNGHEINRICH

Recent Posts:

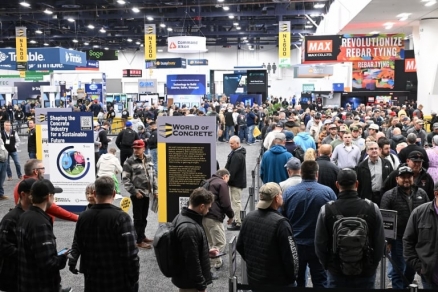

The world’s largest concrete construction and masonry tradeshow encompasses the future of building through leadership and education, integrating technology, solutions and partnerships.World of Concrete, the unmissable and most comprehensive exposition in the world dedicated to the concrete con...

Citeste mai mult

LANDMARK START TO 2025 AS JCB’S HYDROGEN ENGINE APPROVED FOR USE JCB has cleared significant hurdles in its development of the world’s first hydrogen combustion engine after securing landmark rulings from licensing authorities allowing it to be used commercially in machines, the company...

Citeste mai mult

Mr. Maggioni’s CEO role extends to the entire corporate conglomerate, including Raimondi subsidiaries in Turkey and across the Middle EastHighly experienced executive to catalyse aggressive brand internationalization and global growth strategy via M&A and expansion of business linesSenior ...

Citeste mai mult

Hitachi Construction Machinery (Europe) NV (HCME) is pleased to announce the appointment of Mr Francesco Quaranta as its new President and CEO as of 1 April 2024. He replaces Mr Takaharu Ikeda, who will continue in the roles of Chairman of the Management Board at HCME and HCM Regional General Manage...

Citeste mai mult